Stainless steel Hydraulic fittings connect conductors such as hoses, pipes and tubes in a hydraulic system. Most fittings have a male and female component that joins to form a connection. These connections help contain and direct the flow of hydraulic fluid in the conductor while preventing leaks and maintaining pressure. Different fittings allow designers to change flow direction, the elevation of lines or split flow.

Carbon Steel Fitting (Ermeto Fitting)

( Customer review)

Ermeto fittings are tube or pipe fittings type that is used in various industrial applications across world. These fittings suits best to be used in high pressure hydraulic application such as pneumatic and hydraulic lines. The fittings offer as excellent general characteristics that makes is highly popular and efficient fittings material in industries. The product offers excellent corrosion resistance, good stability, improved durability, excellent construction and tolerance for high temperature.We are the most popular industries in the trading and exporting of efficient quality or Ermelo fittings to their buyers across world.

Copper Washer

( Customer review)

The main applications of Copper Machined Washers are roofing, plumbing, industrial machinery and electrical wire. Copper Punched Washers as well provide a number of other excellent attributes like less maintenance, Damage resistance, Easy to use, excellent strength, Simple design.

Dowty Seal

( Customer review)

What is a Dowty Seal? A bonded seal, a metal washer with a vulcanized rubber insert for use in high pressure applications where other means of sealing are unsuitable. The flexing action of the lips under pressure provides a positive and leak proof seal against a wide range of fluids.

Grease Nipple

( Customer review)

A grease fitting, grease nipple, jerk fitting, grease jerk, or Ale mite fitting is a metal fitting used in mechanical systems to feed lubricants, usually lubricating grease, into a bearing under moderate to high pressure using a grease gun.

Hydraulic Brass Fitting

( Customer review)

Brass pipe fittings are basically used for dispatching flammable gases, water, chemicals and other plumbing material. Brass made Pipe fittings are available in ample range of shapes and thread sizes for connecting, or controlling any liquid or gas in pipes.

Hydraulic High Pressure Hose

( Customer review)

High pressure hoses are design for hydrostatic transmission and impulse applications. Each hose is designed to meet or excess SAE specification and performance requirement. We’ve engineered state-of-the-art industrial hoses, couplings and accessories for applications ranging from water to welding, petroleum to pressure washing, and from mining to material handling. And also hoses are compatible with Hydraulic fluid, Vegetables, Oil, Gases, Mining and Manufacturing. Also used in transferring high temp fluids.These are providing optimum performance and flexibility for easier routing and plumbing.

Low Pressure Hose (L P Hose)

( Customer review)

Catering to the demands of customers as a manufacturer, supplier and retailer, we are engrossed in offering Low Pressure Flexible Hoses. Specifically designed by our professionals using superior-grade raw materials, these hoses are widely demanded across the nationwide market. Also, these hoses have flat structure inside and a screw shaped outside.

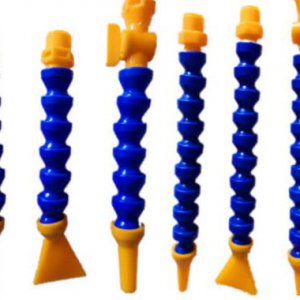

Metal/PVC Coolant Pipe

( Customer review)

Flexible coolant pipes are specially designed to allow coolant flow right on the tool. These pipes help the clients in chemical industry to make huge savings by working efficiently. We have Flexible coolant pipe with and without magnetic base. We also have hose system accessories like nozzle, nipple, reducer/ adapter, Y fittings, I.D. Links etc. We offer these coolant flexible pipes and accessories at most competitive prices.

MS GI Plated Hydraulic Fittings

( Customer review)

Hydraulic fittings connect conductors such as hoses, pipes and tubes in a hydraulic system. Most fittings have a male and female component that joins to form a connection. These connections help contain and direct the flow of hydraulic fluid in the conductor while preventing leaks and maintaining pressure. Different fittings allow designers to change flow direction, the elevation of lines or split flow. Crimping is the most common method for assembling hoses and fittings. Once the crimp specifications have been checked for the specific hose and fitting, a crimping machine is adjusted to the appropriate crimping diameter setting. The next step is to lubricate the fitting, put it on the end of the hose, and then put it in the crimping machine.