Hydraulic section

Hydraulic High Pressure Hose

( Customer review)

Stainless Steel Expansion Bellow Hose

( Customer review)

Stainless Steel Teflon Corrugated Hose

( Customer review)

Stainless Steel Flexible Corrugated Bellow Hose

( Customer review)

Carbon Steel Fitting (Ermeto Fitting)

( Customer review)

Stainless Steel Swagelock Fittings

( Customer review)

Low Pressure Hose (L P Hose)

( Customer review)

Steam Hose/Air Hose/Pneumatic Hose/Jack Hose

( Customer review)

MS GI Plated Hydraulic Fittings

( Customer review)

Hydraulic Brass Fitting

( Customer review)

PVC Clamp/pipe Camp /Aluminum Clamp

( Customer review)

Stainless Steel Cam Lock Coupling

( Customer review)

Quick Realise Coupling

( Customer review)

Suction Stainer (Oil Filter)

( Customer review)

Carbon Steel – Stainless Steel Forged Fittings

( Customer review)

Copper Washer

( Customer review)

Dowty Seal

( Customer review)

Grease Nipple

( Customer review)

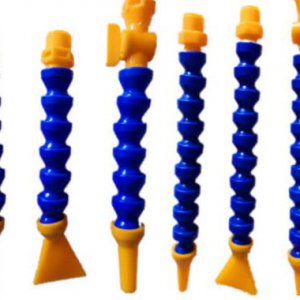

Metal/PVC Coolant Pipe

( Customer review)

MS-SS Hose Clip

( Customer review)

MS-SS Siphone Tube

( Customer review)

Oil Seal, Mechanical Seal, O Ring

( Customer review)

Pressure Gauge

( Customer review)

PVC Braided Hose

( Customer review)Valves and cock section

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status.

Pneumatics section

Pneumatics is a branch of engineering that makes use of gas or pressurized air.

Pneumatic systems used in industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically powered, compressor power cylinder, Air motors and other pneumatic devices, A Pneumatic system controlled through manual or automatic solenoid valve is selected when it provides slower cost, more flexible, or safer alternative to electric in dentistry, construction, mining, and other areas

Round Body Cylinder MAL Series

( Customer review)

Quick Exhaust Valve

( Customer review)

Polyurethene Tubing (Pu Tube)

( Customer review)

Pneumatic Solenoid Operated Valve

( Customer review)

Pneumatic Quick Coupler

( Customer review)

Pneumatic Push In Fitting

( Customer review)

Pneumatic Cylinder Mounting Accessories

( Customer review)

Pneumatic Auto Drain Valve

( Customer review)

Pneumatic Air Regulators

( Customer review)

Pneumatic Air Operated ISO Cylinder DNC

( Customer review)

Pneumatic Air Gun

( Customer review)

Pneumatic Air Fitlter Regulator

( Customer review)

Pneumatic Air Filter

( Customer review)

Pneumatic Air Cylinder Std ISO

( Customer review)

Mechanical And Manual Panel Maounting Valve

( Customer review)

Manually Operated Direction Control Valve

( Customer review)

FRL Unit

( Customer review)

Double Acting Tie Rod Cylinder

( Customer review)

Diaphragm Operated Solenoid Valve

( Customer review)

Compact ISO Cylinder

( Customer review)

Compact Cylinder SDA Series

( Customer review)

Anti Spark PU Tube

( Customer review)

Alluminium Oil Window

( Customer review)